For a million times there, brilliant ideas have been represented by a bulb in popular media (e.g., Felix the Cat cartoons). Perhaps, this symbolism can be traced back to the great inventor, Thomas Alva Edison, who made the incandescent light bulb a reality for everyone on the planet in 1879.

Of course, the wizard of Menlo Park was not the first inventor who tried to make the incandescent bulb happen. Way back in 1802, Humphrey Davey invented the world’s first electric light. After which, the race was on for a commercially feasible light bulb.

What this shows is how the right idea can be a great start to succeed in any endeavor. But it’s never enough. You have to make it work.

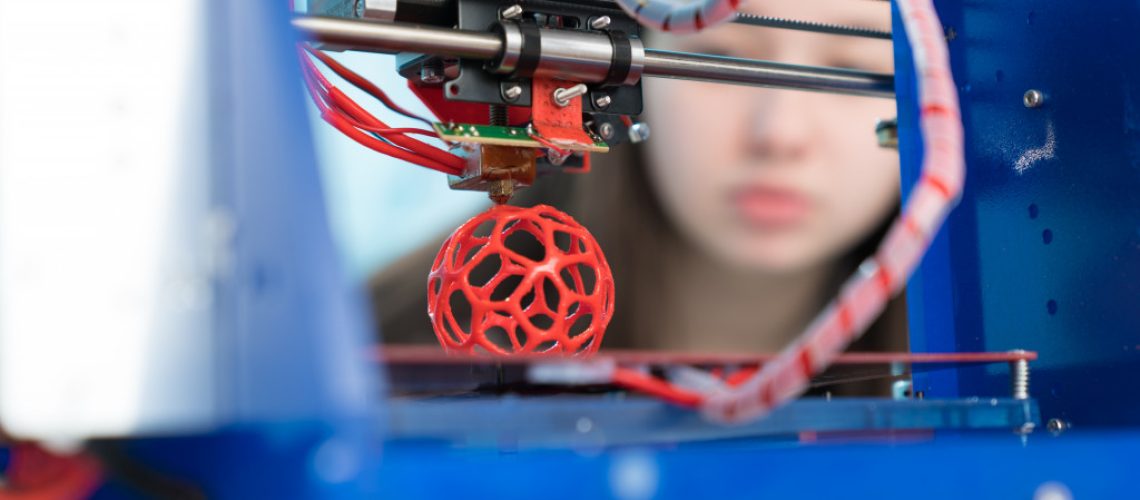

The same pattern emerged in the invention of 3D printers. In 1981, an innovative Japanese industrial researcher saw the merits of photopolymers to fabricate solid prototypes using UV light. The idea was brilliant, but it stalled. Credit Chuck Hull, an American engineer, for the invention of the 3D printer or the stereolithography-capable machine.

It’s easy to be confused about what 3D printing or additive manufacturing is. Indeed, it’s a very technical term. But, this is one idea you really can’t afford to overlook when it comes to expanding your business. After all, there is a slew of industries that have dramatically raised their bottom line thanks to 3D printing.

Aerospace

Many people can’t wrap their heads around 3D printing. And for the most part, it’s because of our mental imprint of what printing is all about. From the very beginning, our idea of printing is a bond paper being printed using a traditional printer such as Canon or HP. Well, that kind of printing is two-dimensional, with movements in the x and y-direction.

On the other hand, 3D printing adds another dimension to 2D printing. And that’s along the z-direction, making objects of all sizes and shapes become a reality.

True enough, the aerospace industry was quick to embrace additive manufacturing — and for a reason. When you fly a machine up in the air, you require the most stringent standards for things to hold steady and not go bust. Certainly, parts must hold up in the harshest of conditions for an aircraft to function best.

But such high standards are very much reachable using 3D printing. By partnering with a reliable 3D additive manufacturing company, aerospace companies saw their innovative designs come to life with the exact precision and speed they need. Some of these involved environmental control systems (ECS) and components for rocket engines.

The advantages are obvious. Not only does 3D printing make short work of the designs of the most complex parts, but it also uses far lesser materials. In short, you end up with highly durable parts that are a lot lighter.

Medical

Another industry that has benefited extremely from 3D printing is the medical industry. Think about every patient that comes and goes to a medical center.

Everyone has their own specific needs. A prosthetic is one. By utilizing additive technology, people can avail themselves of low-cost options. And it’s a lot more accessible for patients who need it most. What’s more, they have the freedom to choose the design and specifics of their prosthetic.

Additionally, future medical practitioners can study the human anatomy better with 3D-printed organs. While a 2D representation in books may be useful for study, having a model that mimics the actual parts of a human body spells a huge difference in their quality of training.

Moreover, with 3D printing, you can replace broken parts of a lab or medical equipment with ease. In the long run, you minimize the downtime and allow a patient greater chances of recovery. Best of all, you save precious dollars in the process.

Transportation

Like the aeronautics industry, the transportation industry exacts a high standard on vehicles. Millions of Americans spend countless hours on the road. Such a life in the fast lane requires vehicles to endure the toughest of terrains at extreme speeds. So to answer such a demand, the transportation industry must have parts that not only stand up to these harsh conditions but also light enough not to cause uncalled-for drag.

Again, this is where additive manufacturing is at its best. With such technology, creating super-complex shapes is a breeze. Indeed, it offers such endless possibilities that those processes being used now are just scratching the surface.

When you can build stronger yet more lightweight components, you end up with vehicles that are as efficient as you want them. A glance at the work that 3D printing has done can make your jaw drop. Top of this list is complex ductwork that is not possible by using conventional manufacturing processes.

All these show how extremely powerful 3D printing is. That this technology can put your business upfront ahead of the competition is a brilliant idea. All you have to do now is to make it happen.